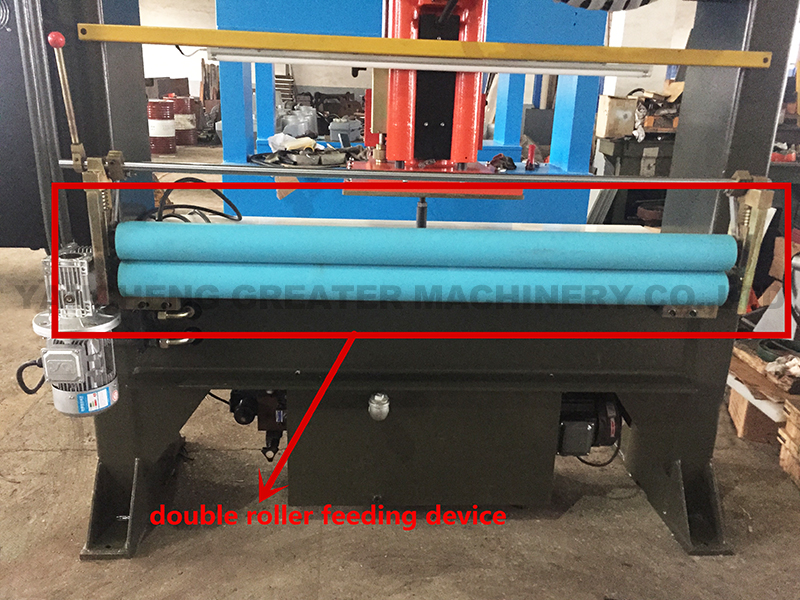

GRT-T Series automatic twin-roller feeding & travelling head cutting machine

USAGE AND CHARACTERISTICS:

1.The machine is applicable to continuous cutting operation of nonmetal rolled materials of same specifications in large batches by cutting die. For example: used in such industries as football, volleyball, tennis, sand paper and medicine etc.

2. Microcomputer controls machine for coordinate movements of horizontal move axle and feeding axle for material cutting action. Besides, the punch head displacement and material-feeding length can be set preciously. This greatly reduces offcut and the material save rate reaches 10%~15%.

3. Several working modes as your options: jogging, manual, and automatic. What workers need to do is only picking up finished product material to reduce labour intensity and raise work efficiency.

4.The machine has cutting modes of stagger, stagger blade reducing and die cutter rotation etc., which can greatly reduce the consumption of materials.

5.As the machine is controlled by microcomputer with high automation degree, only one worker is required for the whole machine, so that the production efficiency can be enhanced for 3-5 times and the power can be almost 1/3 saved.

6.With special setting mechanism, and in conjunction with die cutter and cutting depth setting, the travel adjustment is simple and accurate.

Optional parts:

micro-movement device for cutting board; products of special specifications can be customized.

Technical specification:

Model | GRT-T25 | GRT-T30 | GRT-T35 | GRT-T50 |

Max. cutting force | 25T | 30T | 35T | 50T |

Working table (mm) | 1600×500 | 1600×550 | 1600×550 | 1800×550 |

Travel head size | 500×500 | 550*550 | 550*550 | 550×550 |

Adjustable stroke | 5-150 | 5-150 | 5-150 | 5-150 |

Motor power | 2.2KW | 2.2KW | 3KW | 4.0KW |

Machine’s dimensions (mm) | 2200×620×2000 | 2200×620×2000 | 2200×620×2000 | 2200×620×2000 |

G.W.(Approx.) | 2300kg | 2500kg | 3000Kg | 3500kg |