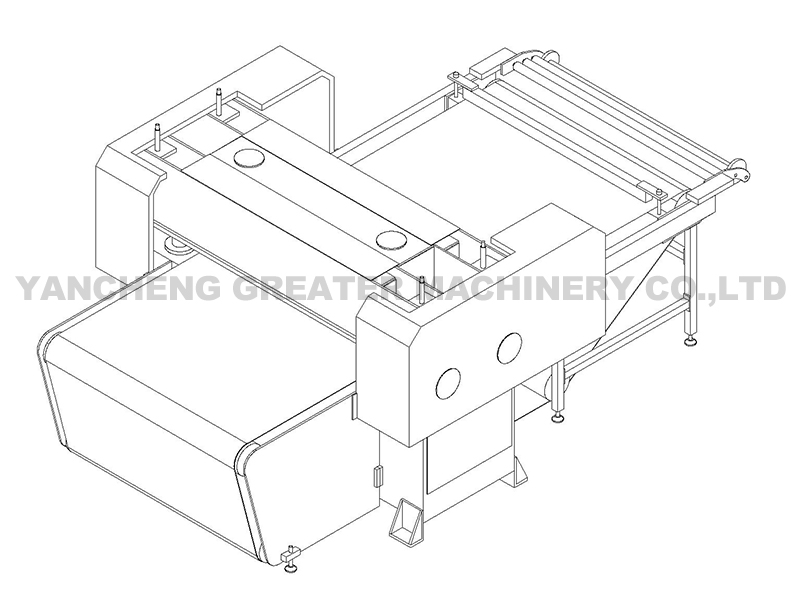

Conveyor belt type precise 4-column plane cutting machine

USAGE AND CHARACTERISTICS:

1. The machine is applicable to continuous and large-batch cutting of nonmetal materials such as carpet, leather, rubber and cloth etc. in large-scale factories by die cutter.

2. The conveying part adopts PLC control. The materials are driven by the servo motor and input from one side of machine, and after die cutting, output from the other side, which can guarantee accurate feeding and stable operation. The feeding length can be adjusted conveniently through touch screen.

3. The main machine is controlled by four-column guiding, double-crank balancing, four-column blocking fine-adjustment mechanism and hydraulic control system, which can guarantee the speed and accuracy of die cutting of machine. All movable connecting parts are equipped with central oil supply automatic lubricating device, which reduces the abrasion to the minimum extent.

4. The input and output of materials are conveyed on the conveying belt, and the die cutting of materials is also automatically completed on the conveying belt.

5. Photoelectric pneumatic deviation correcting device is adopted, which guarantees the accurate operation position of conveying belt.

6. The inlet and outlet of cutting area of the machine are installed with safety screens, which can guarantee personal safety of operators.

7. The die cutter is fastened by pneumatic clamp device so as to make the replacement of die cutter convenient and prompt.

8. Products of special specifications can be customized.

Technical specification:

Model | XCLP3-60 | XCLP3-100 |

Max Cutting Force | 60T | 100T |

Cutting area | 1600×1000 | 1600×1000 |

Tension distance | 25-175 | 25-175 |

Main Motor Power | 5.5KW | 11KW |

Working frequency | 6~12 times/min | |

Feeding servo motor power | 2KW | |

Air source | ≤6kgf/cm2 | |

Weight | 5000KG | 7500KG |